There was no consideration for how to the hold the part, and an order of operations that would allow a real workflow. The program could not make one 0.25" feature because it did not have anĮnd mill small enough. It made toolpaths that were unneeded, like cutting the outside periphery from the bottom after already cutting it from the top.

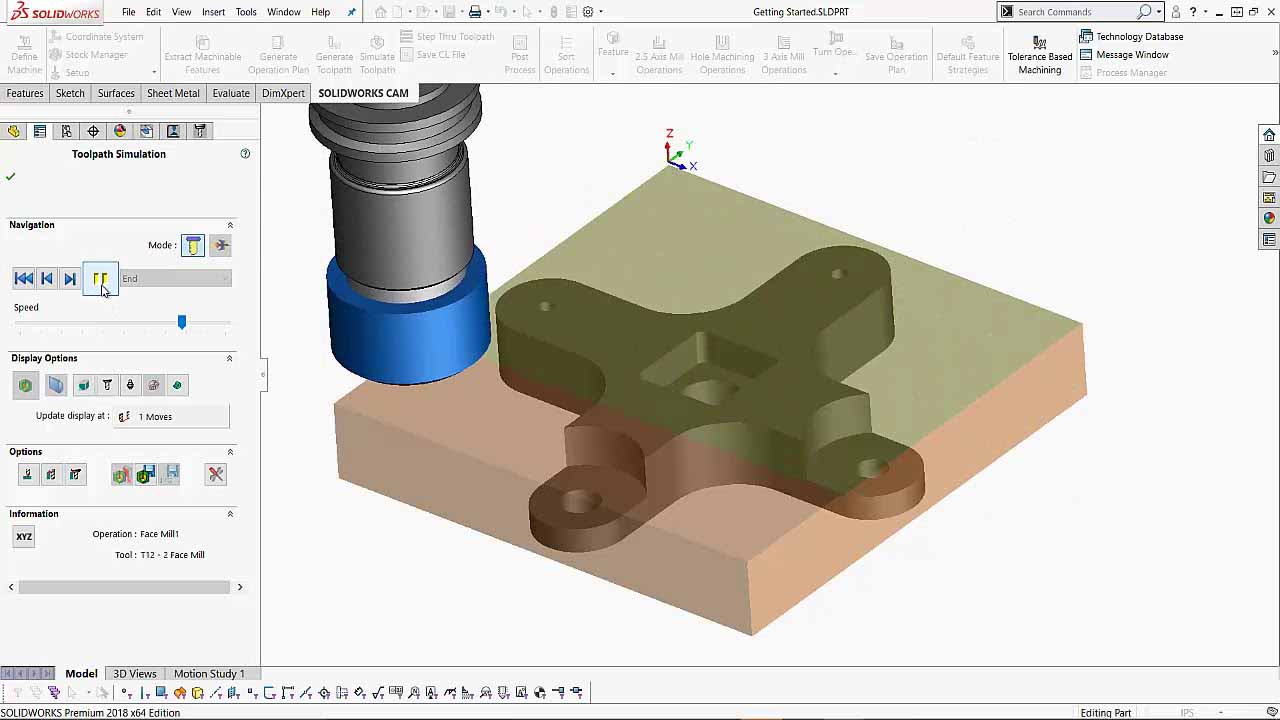

It would make toolpaths around the part that cut all the way into the vise. This is because I let the program automatically recognize features, and then automatically generate operations to make those features. The first impression of Solidworks CAM (computer-aided manufacturing) made CNC tool-paths that were unusable or useless. Rako Studios » Media » Suffering-with-software » Solidworks CAM, CAMWorks second impression Solidworks CAM, CAMWorks second impression SolidWorks 2018 and later has a free CAM (computer-aided manufacturing) add-in to make G-code for milling machines.

0 kommentar(er)

0 kommentar(er)